Sword Engraving

Blade Coloring

Custom Size

Full Tang Katana

Clay Tempered Katana

Folded Steel

Carbon Steel Katanas are appreciated pieces. Forged according traditional methods developed in the Old Japanese civilization, these particular Samurai Swords have a lot of features and so many secrets. According to the Carbon Steel type, the sword inherits lots of particularities and properties commonly known to be characteristics of the material. He, who needs to have a sword, should know exactly why and how he needs his sword to be, which will guide the choice of the material to use in the forging process.

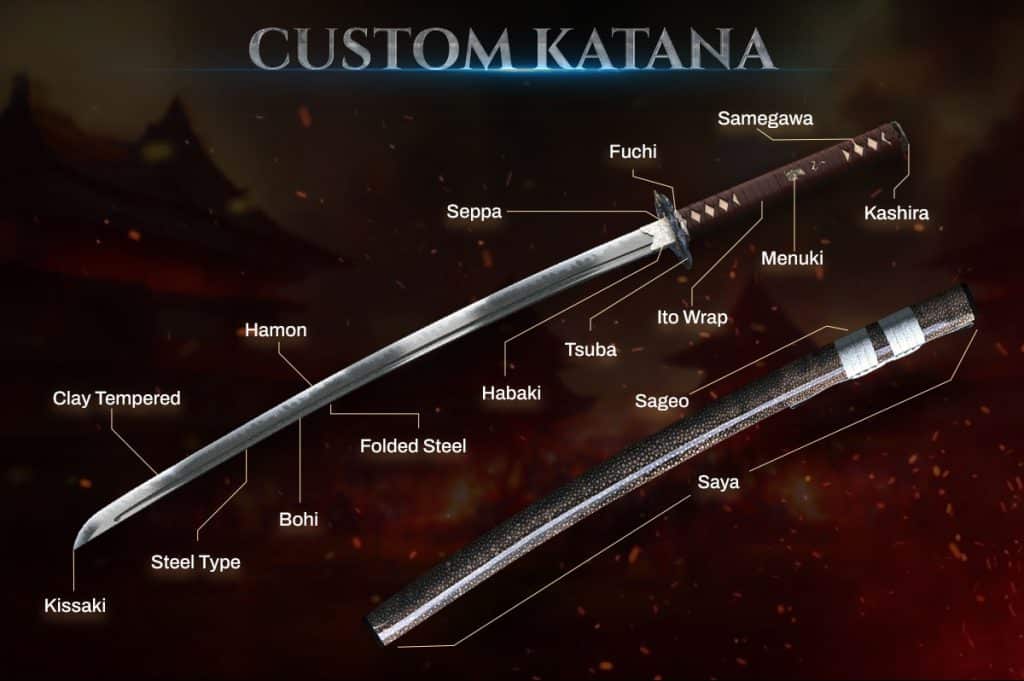

Moreover, the material properties can implicate the parts to mount on the sword to obtain the desired design and serve the intended purpose. For example, choosing the 1095 Carbon Steel type induces the Hardening process, the Hamon type, the Tsuba and more others features are in tight relation with the material type.

1095 Carbon Steel :

The old method to generate Carbon Steel is still employed: mixing iron powder with charcoal within a clay tub. The quantity of each component is determined by the desired Steel type and the intended use. Steel Types are usually produced on demand to make decorative pieces or weapons and Samurai utilities.

Heat treatment is to be operated very carefully because it is a delicate operation: improper treatment can result in loss of the carbon fraction and therefore the non-obtaining of the martensite, which can result in the loss of the whole material. The 1095 Carbon Steel comes to be softer than the Stainless Steel, yet it is easier to handle, durable and more resistant. But among the Carbon Steels, 1095 is the hardest and perhaps the best choice for making swords intended to last longer while being roughly and frequently used.

The Carbon element makes the obtained steel relatively resistant to oxidation even if it has no chromium to be considered stainless. Although, the acquired durability which excels the durability of the Stainless Steel, makes Carbon Steel more preferred for making Swords.

1095 Carbon Steel Katanas

1095 Carbon Steel Katana inherits the hardness and the toughness of the Carbon Steel material. The Swords are intended to regular use and very frequent Dojo cuts. For outdoor displays and shows, 1095 Carbon Steel Katanas are more suitable than the 1060 and 1045 Carbon steel Katanas; the last one is already preferred when it is about decorative use.

The hardness of the Steel makes the forging process into sword a tough operation and increases the price value of the resulting piece, if handmade. This characteristic induces an excellent durability for the 1095 Carbon steel Swords.

The durability and the Edge Sharpness are reinforced by the Differential hardening process. It is important to notice that Clay tempered 1095 Carbon Steel Katana are resistant to corrosion and are more resistant to oxidation; they are perhaps stainless. These swords are easier to sharpen and they do not need to have a thick layer of what the swords men call “meat”; the edge keep its sharpness for long time. The hardness of the 1095 Carbon Steel Katana is inherited from the Steel material used for the forgery. Actually, forging Katanas fusing 1095 Carbon Steel appears to be harder than forging swords from others Carbon Steel types. Thus, the price of a 1095 Carbon Steel Katana tends to be higher.

Although 1095 Katanas are tougher than the others Carbon steel Swords they are still susceptible to abrasion and to corrosion if they are not properly cleaned and carefully maintained. Thus, applying cleaning process and using the recommended oil and tools to proceed may augments the durability of the edges and keep the 1095 Carbon Steel katana’s properties for long time. The toughness of the blade, which allows it to be the favorite choice for frequent functional use, may require particular pieces to mount on the blade to form the final Katana. Already, the Carbon steel type has imposed the forging process.

1095 Carbon Steel Katana are full tang katanas because of the hardness of the material and its resistance to shocks which require a tough handle mounted on a tang that is solid enough. Differential Clay Tempering results in a hardening the edge and keeping the spine softer, this operation may increase the durability of the edge and enhances the resistance to corrosion, therefore the edge will support the frequent dojo cut and outdoor display.

1095 Carbon steel Katanas are usually associated to Ray Skin handle and a hard wooded and lacquered Saya. The blade is preferably to hand polish to keep the traditional touch. It is important to notice that user can suggest the parts and the material they are made of to complete the sword order. In all cases, the hand making process is the guarantee that the 1095 Carbon Steel Katana issued from the forgery is unique; It has been made with the extreme care and the extreme attention to details.

Forging 1095 Carbon Steel Katana :

1095 Carbon Steel Katanas are usually massive, but they do not need to be folded to obtain a hard blade. Adding a blood groove is one practice that may reduce the weight of the blade while keeping the softness of the spine that would counter balance the hardness of the edge. The Sword acquires the curved shape during forging process and Clay Tempering operation: the differential clay application makes that the edge is kept harder.

The quenching cools the edge faster which forces the blade to acquire the curve. Folding the blade steel is to allow the distinction of a visible Hamon which will give the sword a beautiful touch of proficiency. Being hard to forge by hands, 1095 Carbon Steel Katanas for sale are expensive compared to the family’s members. The time that will take forging process is quite long and the efforts to employ are considerable. The compensation is a relatively high price.