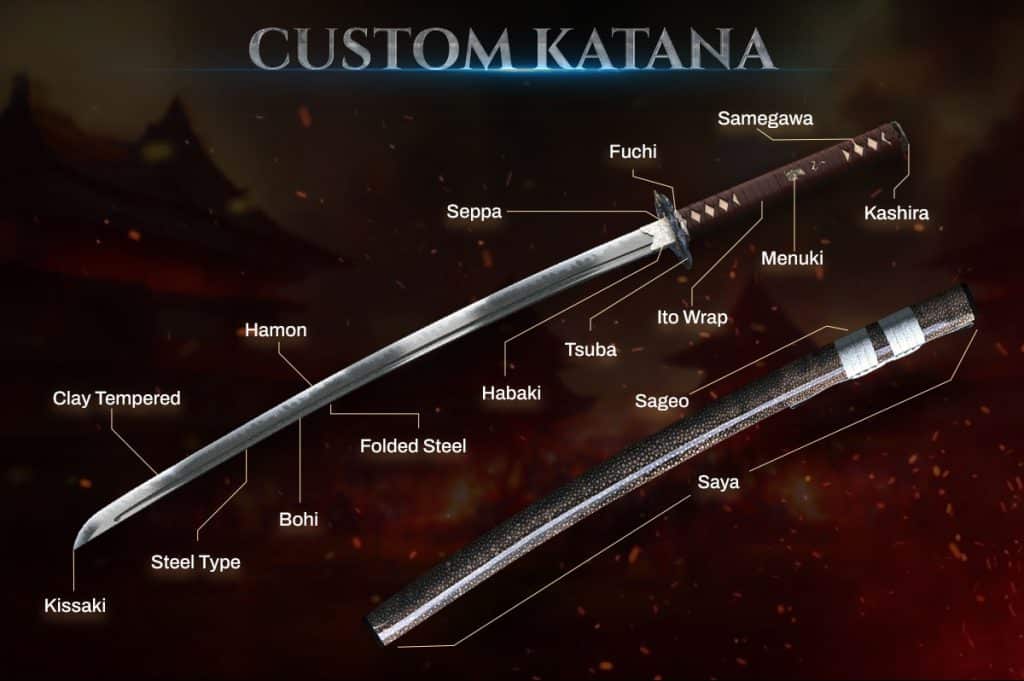

Sword Engraving

Blade Coloring

Custom Size

Full Tang Katana

Clay Tempered Katana

Folded Steel

Legends tell about the mighty powers of the Black Blade Katana . It is a fairy tale suggesting that the black blade is made of a super material that comes from outside the earth and it has the power of casting enchantments up on the carrier or the one it hits.

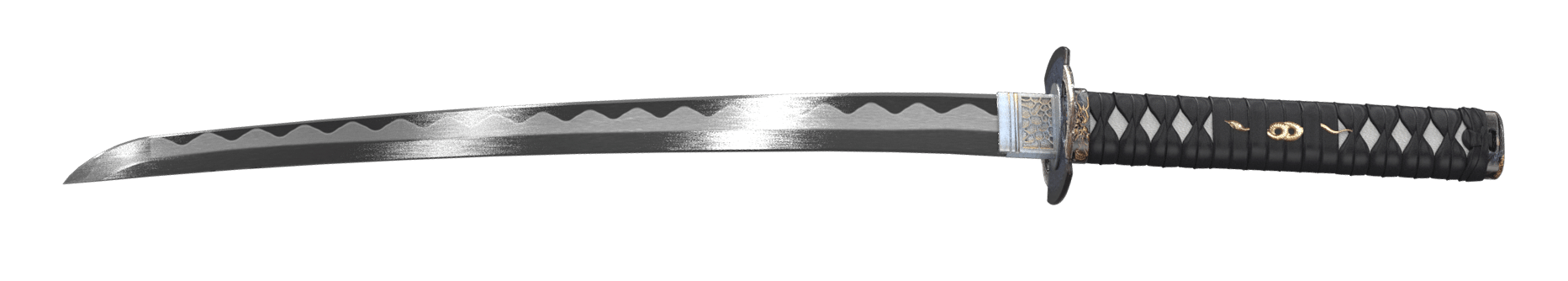

The reality is that the black blade Katana are made of the same steel materials commonly used for Samurai sword making, but at particular steps, the process is slightly modified to obtain the beautiful Black color of the blade. The Hamon, the Blood groove, the Tang morphology, the curve and all the Blade features obey the same traditions as the other swords.

Black Blade Katanas Mythology

Being of tenebrous color, the black blade Katana is considered as an amazing feature you can add to your sword, making it dark and mysterious. the black blade Katana is considered in mythology as an enchanted tool that the carrier is whether an assassin or a hero. most claim it to be made of material coming from outside Earth like a meteor, and usualy considered as a magical black steel that gives the sword some powers.

Our black blade Katana Swords are made of quality steel of your choice, and even tough they can’t give you super powers, they can certainly make a worthy addition to any sword collection. The black coloring is a natural acid dyeing method and it does not harm the blade functionality, swords made of quality steel dyed in black will perform same as a non colored blade

Black Blade Materials

All materials used to forge the black blade Katana keep their known attributes. The issued Katanas inherit the hardness, durability and the determinant properties when choosing the steel material.

The colored blade Katana is certainly capable as it non colored equivalent and will be ready to provide with what you will demand of it: whether the Katana is to be used in casual Tameshigiri or frequent cutting sessions in your backyard. For cutting, or just for decorative purposes.

The black color is acquired after a specific treatment applied on the blade surface; though, as in regular Swords, there are some differences in the suitable methods to use to blacken the blade depending on the material used and the swordsmith.

To acquire the black blade Katana sword, the blade shouldn’t be folded, otherwise the grain pattern will make the blade to appear in red & black.

Join the VIP club and save 10% on your next order

Making Black Blade Katana

Traditional method : Japanese Sword making has developed some process based on Heat treatment which will induce the Katana’s Blade to turn black.

Some other genius methods were developed but the traditional one is the most trusted. The process consists in leaving the forge scale on after heat treatment. The forge scale will form layers. With repetitive heat treatment the forge scale layers will mix with the Steel.

Polishing the blade will bring an awesome effect to a black blade. There is another process that can create the Black colored coat on the blade: it is heat treating the blade carelessly of the oil film that the blade will retrieve during the quenching operation. The processes are to be done with precaution and at very particular temperatures. These operations are suitable for Steel that stands high temperatures and are resistant to heat treatment, notably Spring Steels and High Carbon Steel.

Natural Acid Dye

The acid dyeing method is natural way to create black blade or different color Samurai swords blades. currently we are using this method to create various of options for your sword. You can choose between black, Blue, Gold, Red&black and Purple. For your convenience, here are examples of the different coloring options on different blades.

Colored Blades Available for Non Folded Steel

Blade Colors Available for Folded Steel

Create Your Custom Sword with your preferred Blade Color

Choose every aspect of the sword and we will make it!

Industrial Method

This method consists in coating the blade with Titanium; this operation does not give the blade the stainless properties but it gives it a very beautiful black color that will glow when exposed to light.

The process is known by “Titanium adsorption”. The treatment with Titanium is to be done on polished and sharpened blade, because of the susceptibility of the Titanium coat to corrosion. It is important to notice that Titanium Coating is heat sensitive; the steel types which allow the application of the titanium coat are perhaps all the steel types used in Sword making.

Though it is not a suitable material for making swords, Titanium is employed to enhance the resistance to corrosion and to give the blade the awesome look of a legendary black blade katana but in the real world.

Browse Through Large Collection of Samurai Swords

Titanium Material

There are some Sword smiths who achieve making Katana from Titanium. Actually, this material is not the best choice and it is so far good for making functional Swords.

Actually Titanium can’t hold edges and can’t stand Heat treatment but the element is used to coat blades in a complex form and give them the dark shining look. Therefore, it is not impossible to make sword from Titanium but the process is not worth the efforts and the money.

Colored Blade Katana Coating

There are some steps to make the coating for the blade. the blade will be dyed in the color of your choosing, creating unique look for the sword. Every sword maker has his private method of coloring the blades to obtain a colored blade that looks great and with beautiful dark black steel or different color. this look will not alter the sharpness of the blade but will add a an awesome touch to the sword.

Black Blade Katana Mounting

Blue, Gold, Purple or Black Blade Katana request implicates that the pieces to mount are to be chosen carefully and with fine attention to the color of the blade. According to the Hamon type of the original blade, the blade coloring will be seen more visibly on a differentially hardened blade that was not folded.

it will give the Hamon cool appearance with different colors. The advantage is that the Hamon can be very distinguished because of the contrast that may make the overall dark color of the spine with the edge and the edge meat. Polishing can be done after the coating process but it might have different look with different color options, you can see some available examples in this page.

Tsuka is preferably to be made to fit with the overall color of the blade and ray skin, some prefer a themed black Katana coated with black wrap to ensure the continuity of the dark theme.

The sword off course should be full tang. It is recommended that Saya is chosen to match with the blade and handle style. The quality of the fitting to mount on the blade are to be chosen according the Steel type used to make the blade and your budget.

Whether you are looking for a Black blade Katana or Wakizashi, or even a purple blade Ninjato, we can make all of it as per your specifications. You can visit our custom pages to choose the color of the blade you want, and all other aspects of the sword. Alternatively you can browse through our collection of available swords for sale.